一、Overview of food cold chain

In view of the wet condensation, large amount of steam, multi grease and corrosive liquid in the food processing workshop, the traditional fire detector can not work normally and reliably in this environment. In addition, under the low temperature environment, the fire is relatively slow, but all kinds of thermal insulation materials, packaging materials and other flammable materials in the cold storage are still potential sources of fire. Conveyor and lighting systems, as well as cables, or heat generated during maintenance can also increase the risk of fire. In this case, inspiratory smoke fire detector is a better choice.

And the cold storage is more special than the general warehouse. The temperature of the cold storage is relatively low, usually below zero, generally - 18 °, - 22 °, - 25 °. Some refrigerated warehouses have a use place of - 30 °. The traditional fire detector cannot work normally and reliably in this environment. In addition, in this low temperature environment, the fire is relatively slow, but all kinds of thermal insulation materials, packaging materials and other flammable materials in the cold storage are still potential sources of fire. Conveyor and lighting systems, as well as cables, or heat generated during maintenance can also increase the risk of fire. Moreover, refrigerators usually use large capacity shelves with high height. In case of fire, it is difficult for smoke to reach the detector under the influence of air flow. In this case, inspiratory smoke fire detector is a better choice.

二、Fire characteristics of food cold chain

For the particularity and importance of the cold storage project, we recommend the use of inspiratory smoke fire detector. The temperature of the cold storage will change and it is easy to produce condensate. At present, the ambient temperature of inspiratory smoke detector is mostly between 0 ° - 40 °, so some brands of inspiratory smoke detector put the machine outside the insulation wall, which has several problems:

1. The sampling pipe is placed in the warehouse and the machine is placed outside. There is a large temperature difference between the inside and outside, which is easy to cause air flow failure,

At the same time, the sampling tube will be deformed and bent, which is not conducive to the operation of the machine and brings instability to the normal operation of the machine;

2. The temperature difference between the inside and outside is too large, which is easy to produce a lot of condensate. Many machines need to be installed reversely. If the cold chain water is not treated in time, the sampling pipe will basically freeze and freeze, and the machine will not work normally;

3. The main engine of the inspiratory smoke fire detector is placed outdoors. In summer, the temperature is very high. In this case, the ambient temperature of the main engine is higher than the normal working temperature of the main engine, the machine cannot work normally, and the warehouse is in an unprotected state. At the same time, because the machine is installed outdoors, safety issues should be considered. If the main engine is stolen or damaged, the warehouse is in an unprotected state, In this way, there are great risks for users;

4. When the main unit of the inspiratory smoke fire detector is placed outdoors, a hole needs to be made in the insulation wall to let the sampling pipe connect with the main unit, which will damage the structure of the cold storage and affect the insulation effect of the cold storage. At the same time, if the insulation measures of the peripheral sampling pipe are not done well, the temperature difference between the inside and outside is too large and the sampling pipe is prone to deformation, A large number of internal condensation water will gradually freeze the pipeline, the machine can not normally collect the pipeline smoke information in the warehouse, and the cold storage will be in an unprotected state.

ASD series inspiratory smoke fire detector can work normally in the environment of - 40 ° to 70 ° and can be directly installed in the cold storage to avoid the failure caused by the excessive temperature difference, which is conducive to the stable operation of the machine. When the main engine is placed in the cold storage, it does not need to worry about the safety and use environment of the machine. At the same time, the machine is directly installed in the cold storage, which will not damage the wall and shadow of the cold storage The heat preservation effect of the refrigerator. We also have professional calculation software that can simulate the place of use, so that the size of sampling holes, the spacing between holes, and the alarm time can be displayed very clearly, which can meet the requirements of relevant fire codes.

三、Food cold chain warehouse solution:

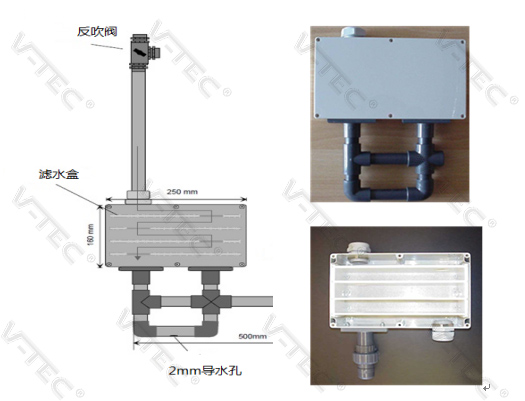

冷凝水处理装置

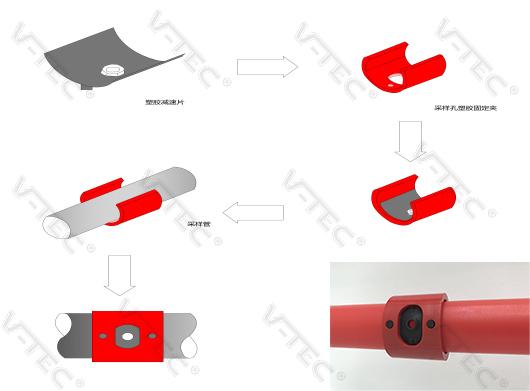

Special device anti freezing clamp

Through the professional design and development of the special anti freezing clamp with patented technology for cold storage, the device can effectively avoid blocking the sampling hole due to the direct blowing of the cold fan or the frequent change of temperature in the cold storage. At the same time, combined with the anti blowing device, even if the sampling is blocked, it can be easily solved

Serve you 24 hours, solve your needs and share your doubts

| TEL:021-51090861 E-MAIL:office@v-tecfire.com FAX:021-37560538 ZIP CODE:210040 ADD:Third floor, building 2, No. 6400, Hangnan Road, Fengxian District, Shanghai China |

To eliminate fire and build social security with innovative technology